Quality Auto Works Fasteners are manufactured under a strict Quality Control Program – Raw material Inspection, In-process Inspection, on-line Inspection of finished products with a modern Quality Assurance Lab – a fool-proof system of checks and controls at every step with value added services that ensures compliance to product specifications and performance criteria.

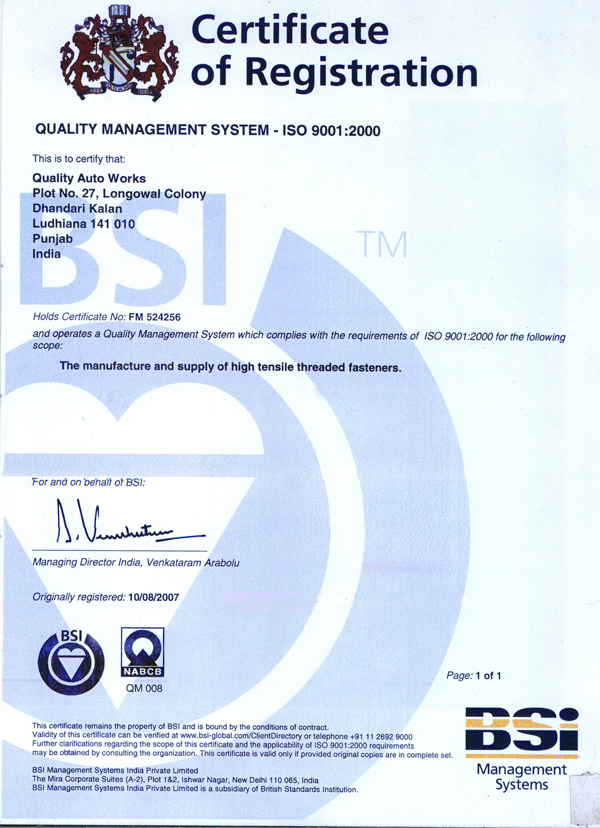

Our quality and calibration systems are in full compliance with ISO 9001. It is our continued commitment to achieve zero defects and provide the highest quality in the industry.

It's no secret that Quality Auto Works has won the admiration and support of OEM customers and distributors and fastener suppliers. Truly recognition it deserves resulting from its long history of bringing diversified quality manufactured products since its inception in 1995.

As part of our strict quality assurance program, our fasteners are required to pass several critical inspections during and after manufacturing. Parts are randomly selected, inspected and analyzed using advanced statistical techniques and we have full SPC (Statistical Process Control) capability. In addition to visual and dimensional inspections, each lot of fasteners is subjected to a series of metallurgical and physical testing. These include micro/macro evaluation, hardness, shear, tensile, torque, fatigue, stress durability and other tests as required by contract

We take great pride in the level of quality and service we provide. Delivering world-class quality parts is more then just a catch phrase and quality statement. It is an essential and continuous part of every transaction, manufacturing operation, process, and telephone call from first contact to final delivery and installation of each product.

Optimum quality necessitates the use of the most up-to-date testing and control systems. Extensive and systematic testing procedures during all phases of production ensure the high quality of Quality Auto Works products.

A commitment to Uncompromising Quality, Responsive Service and Competitive Pricing.

Quality Control Activities

- ISO-9001 certification

- Problem solving techniques are applied to solve development & production issues.

- Quality circles in different areas of shop floor.